Introduction

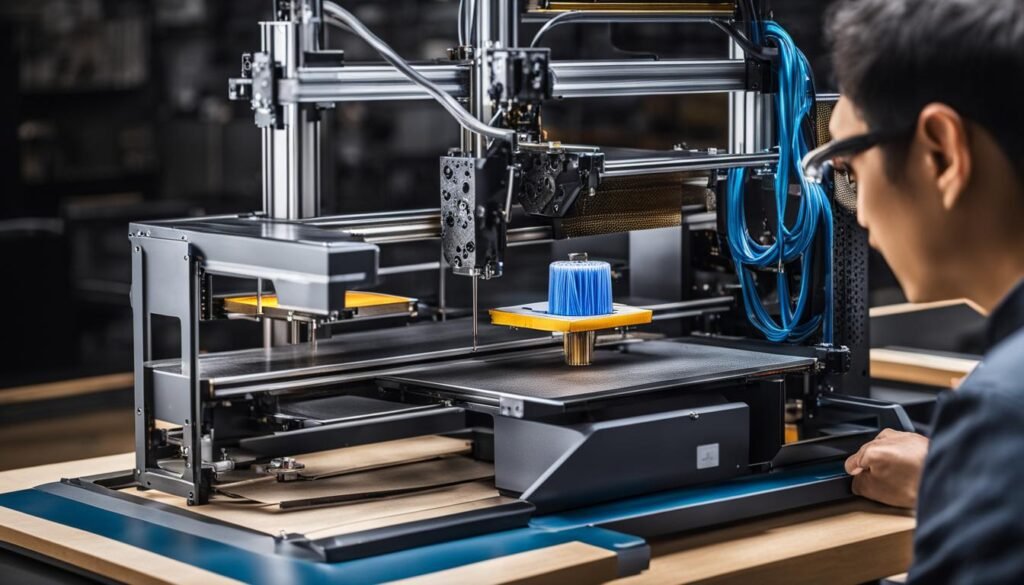

3D printing has evolved from being a futuristic concept to an essential part of modern manufacturing. In 2025, it is no longer limited to prototypes and hobbyist creations—it is a powerful tool driving breakthroughs in aerospace, medicine, automotive, construction, and consumer goods. According to Grand View Research, the global 3D printing market size is expected to reach $76.16 billion by 2030, growing at a CAGR of 20.8%.

This growth is being fueled by innovations in speed, materials, software, and scalability. In this comprehensive guide, we’ll cover the top 10 innovations in 3D printing technology for 2025 and why they matter for industries and individuals alike.

1. High-Speed Fused Filament Fabrication (FFF) Printers

For years, one of the biggest challenges with FFF (fused filament fabrication) printers was speed vs. quality. Prints often took many hours or even days. In 2025, that problem is being solved.

What’s New?

- Advanced Motion Systems: CoreXY and tool-head designs reduce vibration and increase speed.

- Multi-Extruder Systems: Tool changers allow simultaneous or sequential material printing.

- Smarter Cooling: Optimized airflow prevents warping at high speeds.

Example:

- Bambu Lab X1 Carbon can print at speeds up to 500 mm/s, producing high-quality results in a fraction of the time.

- Prusa’s latest tool-changer printer supports up to four print heads, making it possible to mix different materials seamlessly.

Why It Matters

- Startups can prototype within hours instead of days.

- Small-batch manufacturers can produce consumer-ready products at scale.

- Hobbyists gain access to professional-grade quality without enterprise budgets.

✅ Future Outlook: Expect FFF printers to become the “workhorses” of offices, design studios, and even classrooms by 2030.

2. Multi-Material & Full-Color Printing

Single-material printing limited the realism of prototypes. But in 2025, full-color and multi-material printing is not just possible—it’s becoming mainstream.

What’s New?

- Resin Mixing Technology: Printers can now blend colors and transparencies.

- Material Compatibility: From flexible rubbers to rigid plastics in the same print.

Example:

- Stratasys J850 Prime enables seven different resins in one print, simulating glass, metal, skin, and rubber-like textures.

- Dental companies use these printers to create realistic training models with nerves, bones, and soft tissues replicated.

Why It Matters

- Design: Prototypes now look like finished products.

- Medicine: Surgeons practice on models that match human anatomy.

- Education: Students can visualize complex structures in 3D.

✅ Future Outlook: Expect color-accurate product prototyping to reduce design cycles by up to 40%.

3. Metal 3D Printing at Industrial Scale

Metal additive manufacturing has moved from aerospace labs into mainstream production lines.

What’s New?

- Binder Jetting: Allows mass production of metal parts at lower costs.

- Laser Powder Bed Fusion (LPBF): Improved with multiple high-power lasers.

Example:

- HP Metal Jet S100 enables mass customization of automotive parts like gear knobs and brackets.

- GE Aviation produces metal turbine blades using 3D printing, saving 25% in material costs compared to traditional methods.

Why It Matters

- Aerospace can create lighter aircraft parts, improving fuel efficiency.

- Automotive manufacturers can produce on-demand replacement parts.

- Healthcare uses it for custom titanium implants tailored to patients.

✅ Future Outlook: By 2030, 20% of spare parts in automotive may be produced on-demand using metal AM.

4. Construction 3D Printing

Housing shortages and sustainability concerns have made 3D-printed buildings more relevant than ever.

What’s New?

- Large-Scale Concrete Printing: Printers can now extrude concrete with precision.

- Hybrid Construction Methods: Combining traditional and printed structures.

Example:

- ICON, in partnership with NASA, is developing 3D-printed habitats for the Moon and Mars.

- COBOD’s BOD2 printer has built 3-story office buildings in Europe.

Why It Matters

- Affordable Housing: Houses can be built in under a week.

- Disaster Relief: Rapid construction after earthquakes or floods.

- Sustainability: Uses less material and generates less waste.

✅ Future Outlook: By 2035, 3D-printed construction could reduce global housing shortages by 15–20%.

5. Continuous Fiber Reinforcement (CFR)

Plastic prints often lack durability—but when combined with fibers like carbon or Kevlar, they rival metals.

What’s New?

- In-Process Reinforcement: Embedding fibers during the print.

- Hybrid Material Blends: Strong yet lightweight composites.

Example:

- Markforged X7 printer integrates carbon fiber reinforcement, producing parts as strong as 6061 aluminum.

- Boeing uses CFR components to reduce aircraft weight.

Why It Matters

- Aerospace gets lighter planes with lower emissions.

- Automotive builds safer yet lighter vehicles.

- Manufacturers produce strong, custom tools on-demand.

✅ Future Outlook: Expect CFR parts to dominate aerospace and automotive engineering by 2030.

6. AI-Driven Generative Design & Software Platforms

The hardware gets all the attention, but software is the real backbone of innovation in 2025.

What’s New?

- AI-Powered Generative Design: Software suggests the most efficient shapes and structures.

- Digital Twins: Simulations predict how parts will perform before they’re printed.

Example:

- Materialise CO-AM integrates the entire 3D printing workflow into one connected platform.

- Autodesk Fusion 360 uses AI to generate lattice structures, reducing weight by up to 60%.

Why It Matters

- Efficiency: Less trial and error.

- Cost-Savings: Reduces failed prints and material waste.

- Innovation: Designers can create geometries impossible with traditional methods.

✅ Future Outlook: AI will reduce design-to-print time by half within the next decade.

7. Micro & Nano 3D Printing

Not all 3D printing is big—sometimes it’s smaller than a grain of sand.

What’s New?

- Two-Photon Polymerization (2PP): Printing at nanometer precision.

- Micro-Materials: Specialized resins for biomedicine and optics.

Example:

- Nanoscribe Photonic Professional GT2 prints microscopic lenses for cameras and sensors.

- Biomedical researchers are creating nano-needles for drug delivery.

Why It Matters

- Healthcare: Micro-devices can target cancer cells.

- Electronics: Smaller, more powerful chips.

- Optics: Tiny, precise lenses for satellites and phones.

✅ Future Outlook: By 2035, nano-printing will be standard in biotech and electronics manufacturing.

8. Sustainable & Bio-Based Materials

The future of 3D printing isn’t just about innovation—it’s about responsibility.

What’s New?

- Plant-Based Plastics: Polymers derived from renewable crops.

- Recycled Filaments: Plastic waste converted into 3D printer feedstock.

Example:

- Arkema Rilsan PA11, made from castor beans, is now widely used in automotive parts.

- BASF’s rPET filament comes from recycled bottles.

Why It Matters

- Reduces reliance on petroleum-based plastics.

- Lowers carbon footprint.

- Aligns with global sustainability goals (UN SDGs).

✅ Future Outlook: By 2030, half of consumer 3D prints could use recycled or bio-based materials.

9. High-Performance Polymers for Aerospace & Medical

Some industries demand heat-resistant, sterile, and high-strength polymers.

What’s New?

- PEEK & PEKK: High-performance plastics now available in filament and powder form.

- Certifications: Meeting aerospace and FDA standards.

Example:

- Stratasys ULTEM 9085 is FAA-approved for aircraft interiors.

- Medical implants using PEEK are custom-printed for patients, reducing surgery times.

Why It Matters

- Safer, lighter airplanes.

- Tailored medical solutions.

- Industrial-grade parts in extreme environments.

✅ Future Outlook: High-performance polymers will replace metals in aerospace interiors and surgical tools by 2035.

10. Hybrid & Tool-Changing 3D Printers

Why settle for one function when you can have several in one machine?

What’s New?

- Hybrid Machines: Combine 3D printing with CNC milling or laser engraving.

- Tool-Changer Systems: Swap print heads automatically.

Example:

- Prusa CORE One supports multi-material, multi-process workflows.

- Snapmaker Artisan combines 3D printing, CNC, and laser cutting.

Why It Matters

- Cost-Efficiency: One machine replaces three.

- Versatility: Perfect for small workshops.

- Productivity: Switch between processes without manual setup.

✅ Future Outlook: Expect hybrid machines to dominate maker spaces and small businesses by 2030.

Quick Comparison Table

| Innovation | Example Companies | Key Impact |

| High-Speed FFF Printing | Bambu Lab, Prusa | Faster prototyping, multi-materials |

| Multi-Material & Full-Color | Stratasys | Realistic prototypes, medical models |

| Metal AM at Scale | HP, GE, SLM | Industrial metal production |

| Construction 3D Printing | ICON, COBOD | Affordable housing, infrastructure |

| Continuous Fiber Reinforcement | Markforged | Strong, lightweight parts |

| AI & Generative Design | Autodesk, Materialise | Optimized designs |

| Micro & Nano Printing | Nanoscribe | Biomedical & microelectronics |

| Sustainable Materials | Arkema, BASF | Eco-friendly manufacturing |

| High-Performance Polymers | Stratasys, Roboze | Aerospace & medical |

| Hybrid Tool-Changing Printers | Prusa, Snapmaker | Multi-process versatility |

Conclusion

3D printing in 2025 is no longer a supporting tool—it’s driving industrial revolutions across multiple sectors. From printing homes and aircraft parts to microscopic medical devices, these innovations are shaping the next generation of technology.

The key takeaway is that 3D printing has moved from possibility to practicality. With faster machines, sustainable materials, and smarter software, industries can reduce costs, speed up development, and push creative boundaries like never before.

FAQs:

1. What is the biggest innovation in 3D printing in 2025?

The biggest innovation in 2025 is high-speed, multi-material 3D printing that combines speed, precision, and material diversity. This allows industries to produce functional prototypes and finished products in a matter of hours rather than days.

2. How is 3D printing changing the construction industry?

3D printing is revolutionizing construction by enabling large-scale concrete printing. This allows companies to build affordable homes, offices, and even disaster relief shelters much faster and with reduced material waste.

3. Can 3D printing be eco-friendly?

Yes. In 2025, many printers use recycled plastics, bio-based polymers, and plant-derived materials, making 3D printing far more sustainable compared to traditional manufacturing.

4. Is metal 3D printing affordable for small businesses?

While industrial metal printers remain costly, new technologies like binder jetting are making on-demand metal part production more affordable for small to mid-sized businesses.

5. What industries benefit the most from 3D printing innovations?

Key industries include aerospace, automotive, healthcare, construction, and consumer goods. Each benefits from faster prototyping, reduced costs, customized production, and innovative materials.